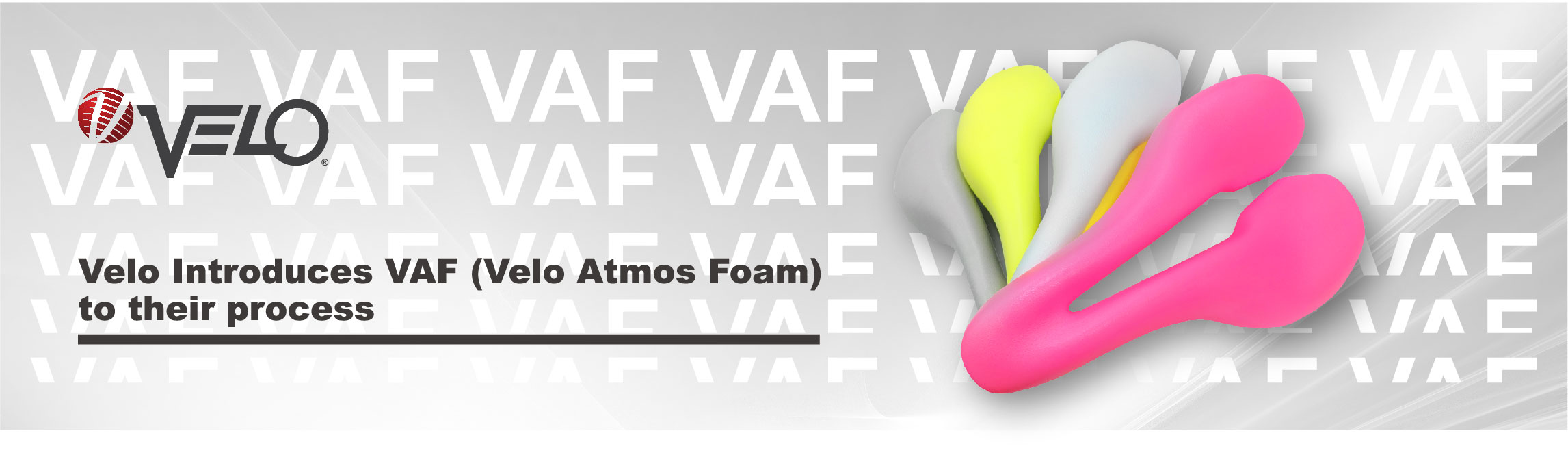

Velo Introduces VAF (Velo Atmos Foam) to their process

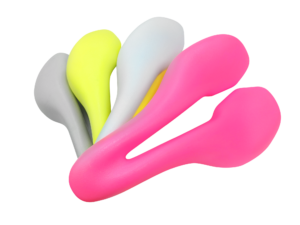

Velo has introduced a new material called Velo AtmosFoam (VAF) which was created to enhance performance and durability attributes while minimizing the environmental impact of the production process. AtmosFoam is lightweight, has incredible support for your sit bones to bring you better overall comfort and performance. The material has been widely used in the footwear industry in the last decade and now Velo has brought the same technology to the bicycle saddle.

“We are excited to be the first to introduce this type of foam to the cycling industry. Velo is continuously looking for innovative ways to increase the performance and comfort of cyclists and researching eco-friendly manufacturing methods,” said Ann Chen, Vice President of Velo Saddles.

Velo AtmosFoam uses nitrogen in the foam production process. Nitrogen is the most abundant element –it’s in the soil under our feet, in the water we drink and in the air we breathe. The VAF nitrogen forming process eliminates the use of chemical additives. Additionally, VAF helps reduce CO2 emissions, creating a more eco-friendly production process. VAF is lighter and more responsive compared to other foam compounds with finer pore structure. The microcells in VAF are more evenly distributed providing consistent rebound and shock absorbing capabilities. The new foam also provides lower thermal conductivity keeping the contact with the saddle cooler in hotter weather conditions. The Velo AtmosFoam will be available in Velo’s aftermarket models and for OEM/ODM customers.

The introduction of Velo AtmosFoam is just one of the recent steps that highlights Velo’s commitment to a more sustainable future and improving the social, economic and environmental well-being of our planet.